AViTEQ VIBRATION TECHNOLOGY

AViTEQ screening technology: all-rounder for dewatering

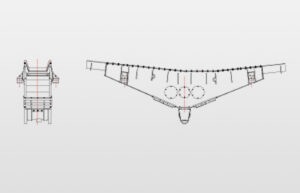

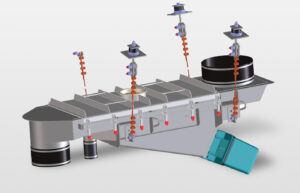

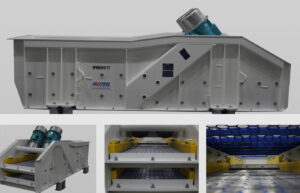

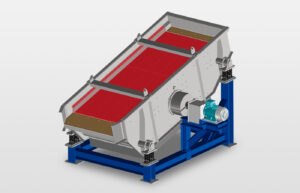

AViTEQ Dewatering screens are linear vibrating screens specially developed to ensure the reliable separation of water or other liquids from solid-liquid mixtures. They are used for dewatering sand, plastic granulate, kieserite, limestone, coal and similar raw materials. Without further drying steps, a reduction of residual moisture to 12% can be achieved with sand, for example. They are also used to remove insoluble impurities from washing water or carrier liquids. AViTEQ also offers special dewatering screens that meet the high hygiene standards in the food industry.

Fast and variable

Our linear systems achieve twice the specific screening capacity compared to flat screens for dewatering. With lengths of up to 5,000 mm and widths of up to 2,800 mm, throughput rates of up to 200 m³/h are possible with AViTEQ dewatering screens. Our screens are available in single-deck or multi-deck design, with magnetic vibrators, unbalanced motors, exciters and circular vibrators available as drives. Thanks to this variability, we can equip our systems at any time according to your requirements and with regard to the individual range of tasks specified by you.

WE ARE THERE FOR YOU PERSONALLY

Simply get in touch with us

As a specialist for individual solutions, we know that nothing can replace direct contact. We are therefore happy to answer your questions, projects and concerns personally. Simply use our contact form - we will get in touch with you as soon as possible.